Production from 50 to 100 000+ pieces. Ready elements even in 14 days.

We are a tool shop and an injection moulding shop - we produce injection moulds on our own and then carry out the production of parts on injection moulding machines. We do not use intermediaries.

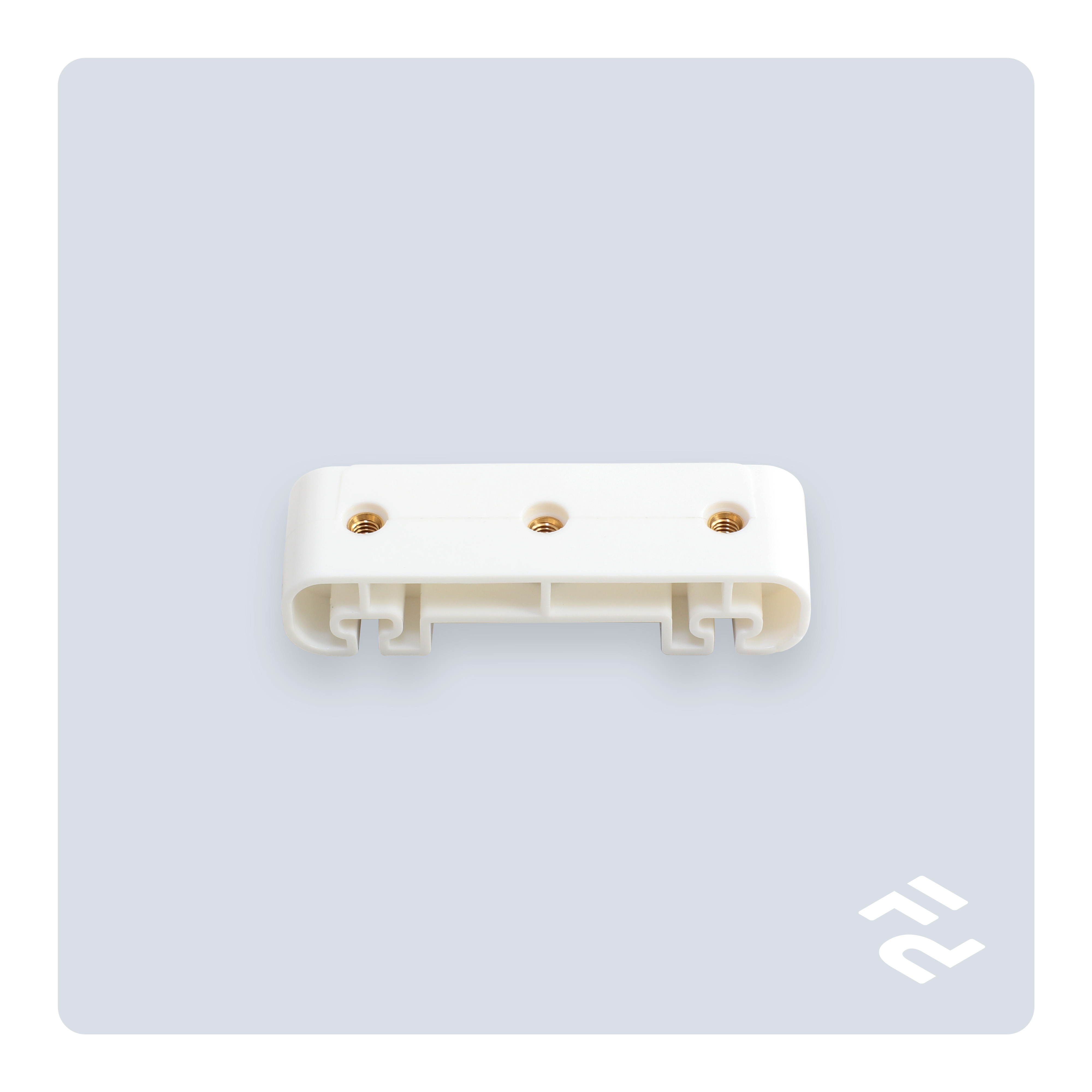

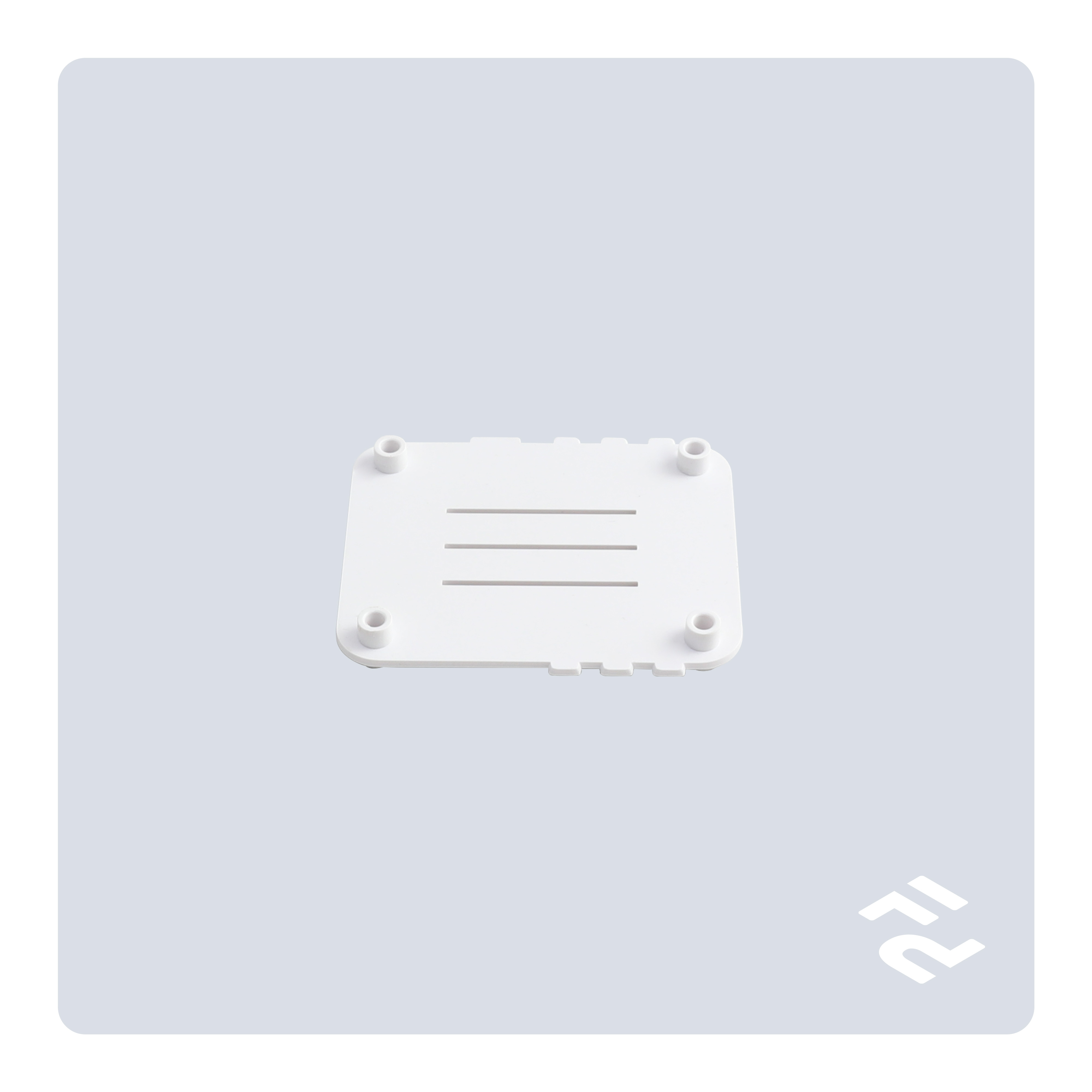

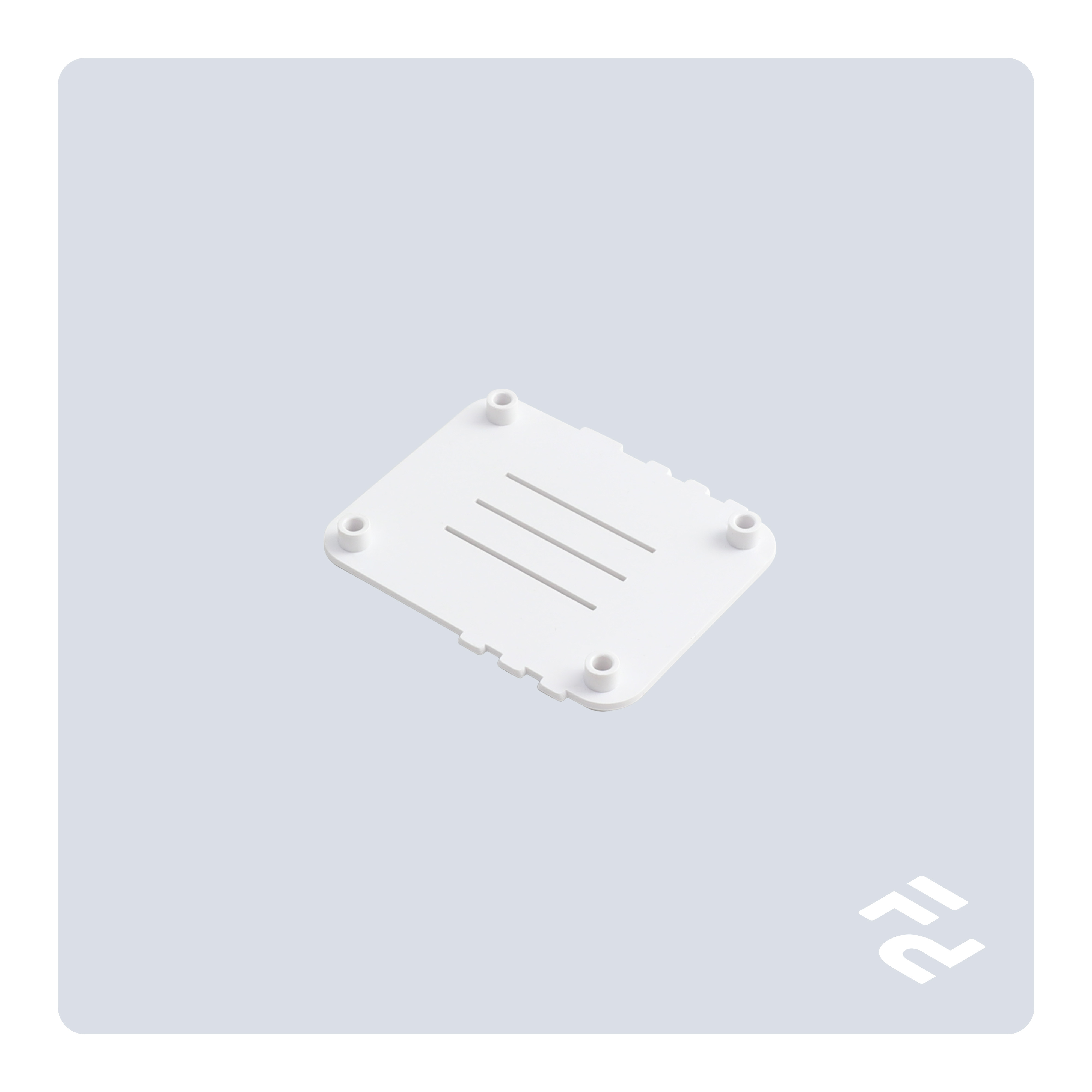

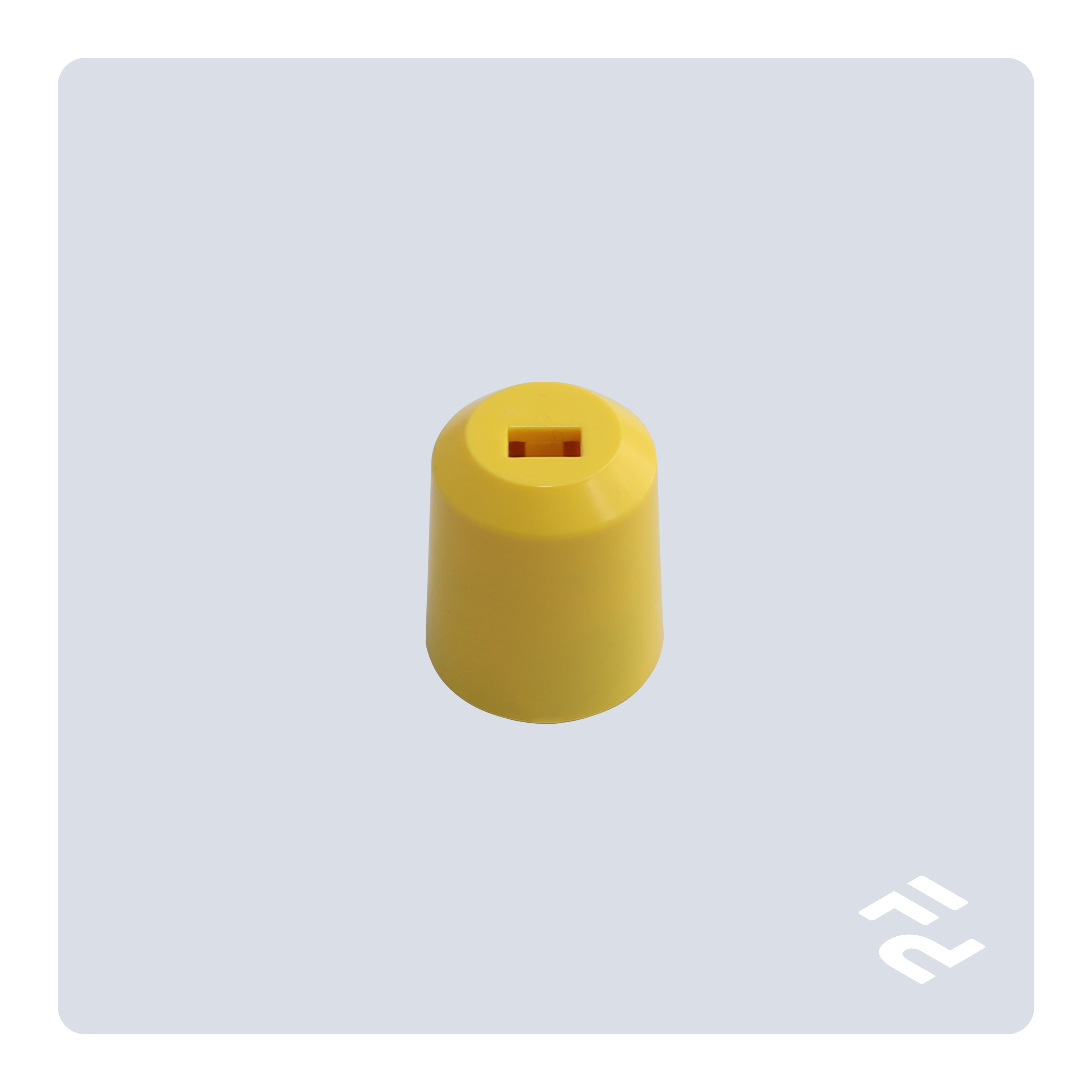

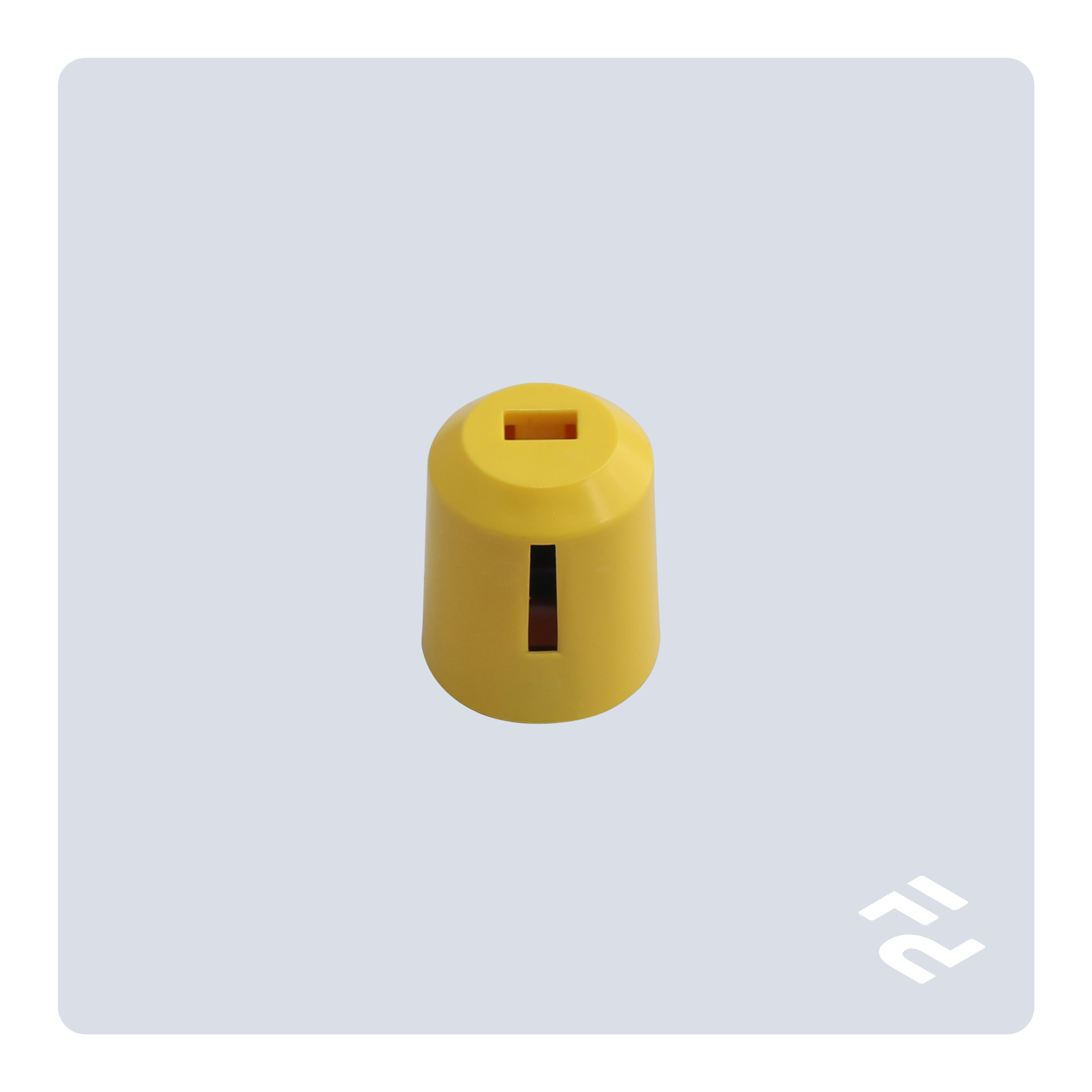

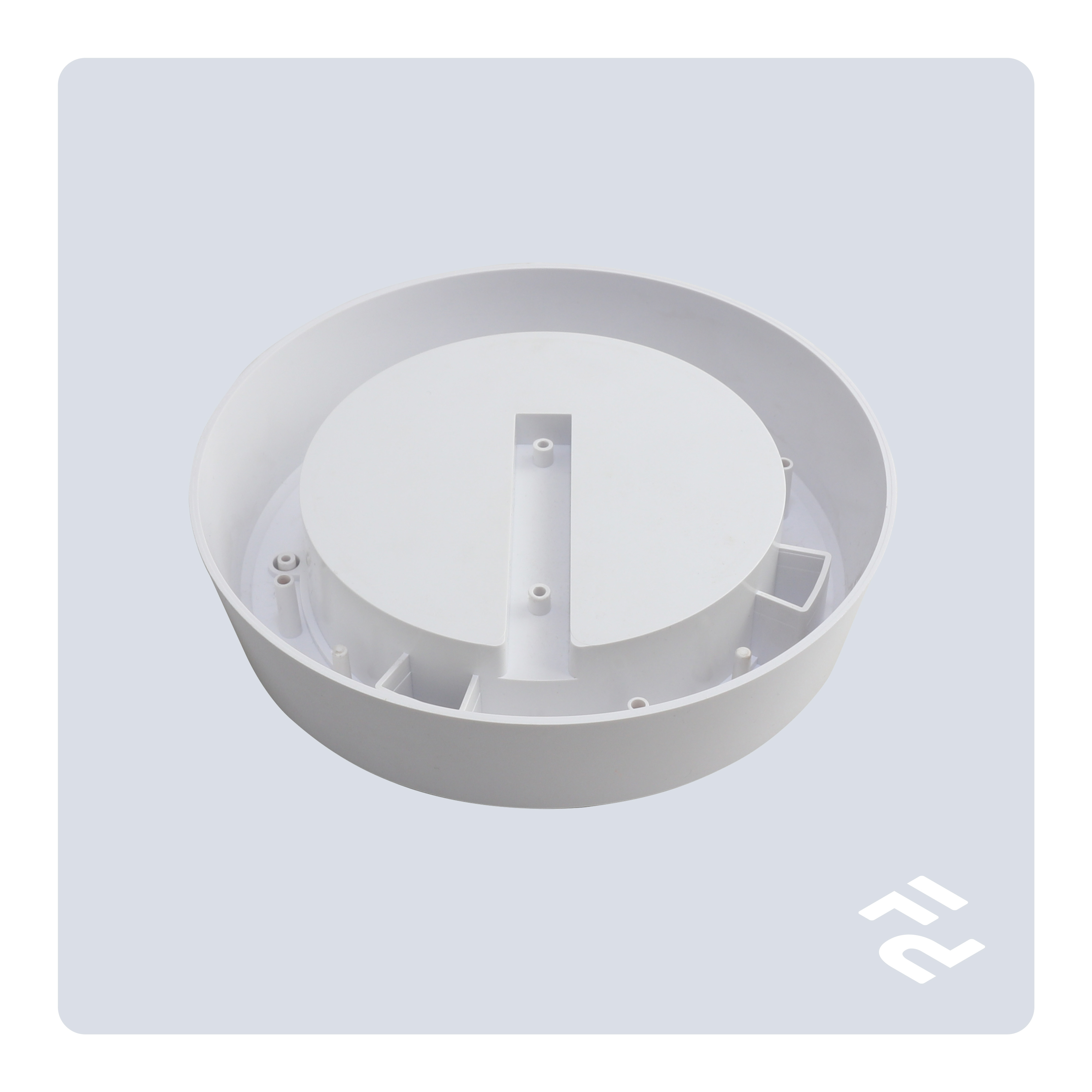

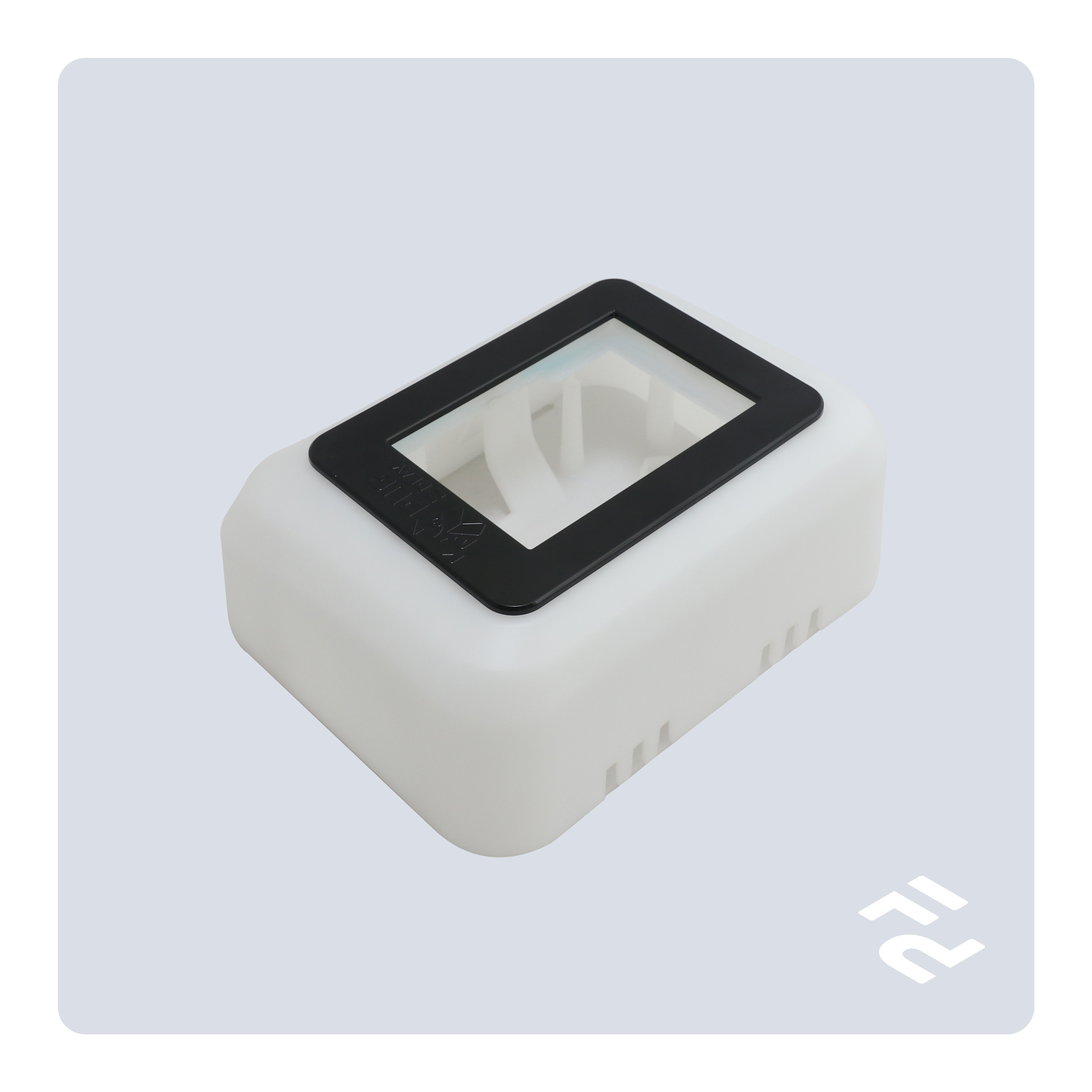

Our mould making technology is uniquely fast and affordable. We offer a wide range of production materials, including polypropylene (PP), polyethylene (PE), ABS, polycarbonate (PC), polyamide (PA), elastomers and many others. Manufactured elements are characterized by high strength and very good surface quality Check the basic list of materials with descriptions.

3DForce - our goal is to deliver plastic parts quickly. We produce moulds starting at 2 000 EUR net!

Quote online now

No production limit. If a mould is destroyed, we produce a new one. No extra charge.

We guarantee very high quality and dimensional accuracy - even up to 0.1 mm. As a standard you can choose from a variety of surface finish options - high gloss, different types of mats.

Check out some of our molds >>

English

English Polski

Polski Spanish

Spanish Deutsch

Deutsch